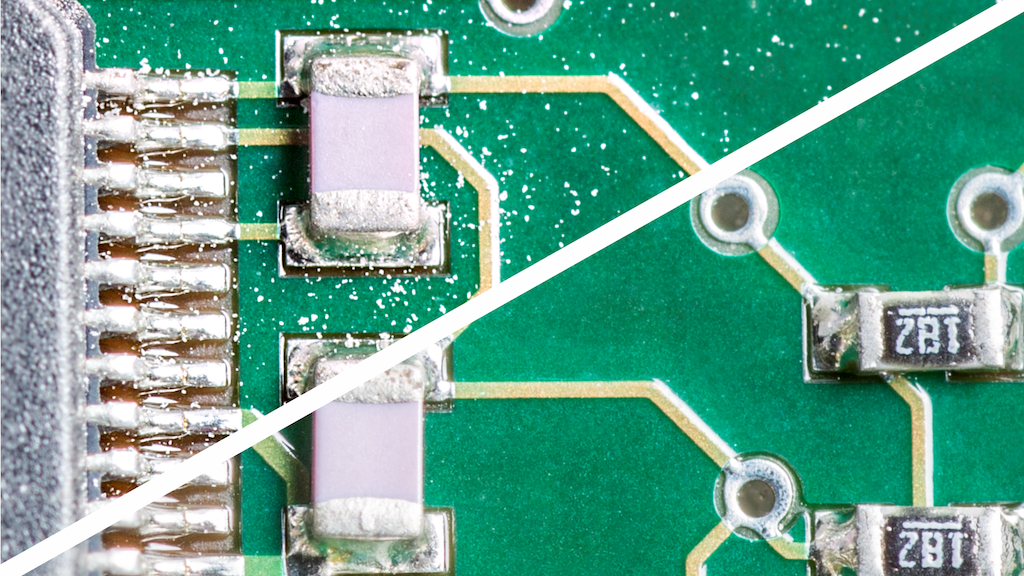

Electromobility: Dust on sensitive components can cause damage worth millions

Dust under the electron microscope

Production conditions for the emerging field of electromobility, as well as already existing production processes for electronic components, require high standards of cleanliness with so many sensitive assemblies. Dust and general contamination can infiltrate into the production areas of e.g. sensitive electronic components, and impair their function. If impurities land on microscopically small conducting paths, a short circuit might result, leading to the malfunction of the component. This problem multiplies with increasing mass production and can affect entire production batches. Damages resulting from new production can be enormous. In the worst case, recall actions are required, which can cost millions.

Personnel airlock, vehicle plant

Personnel can put on appropriate clothing in the airlocks and thus prevent the entry of contamination. TRESOLID from Bad Wildungen has many years of experience in this field in the particularly demanding pharmaceutical and medical technology sector and also offers adapted solutions for the automotive industry. In addition to consulting, 3D conception and production, the medium-sized company from Hessen also offers assembly and sealing by its in-house team. TRESOLID attaches particular importance to quality and well thought-out, functional product design.

- Personnel sluice, vehicle plant

- Personalschleuse, Fahrzeugwerk

- Personalschleuse, Fahrzeugwerk

- Stauraum Personalschleuse, Fahrzeugwerk